Other than wanting to spend very little money on this project, the scope of it is huge enough that I’ve been trying to use as many prebuilt components as possible.

If I have the majority of the project build with discrete, modular components, then I can start drilling down and replace the weakest links, one at a time.

Because the CNC portion is horribly complicated, and itself comprised of several parts (drive electronics, mechanical movements, control software, firmware), several weeks ago I made the decision to use a low-cost CNC platform. I mean “platform” in the sense that it’s designed as a starting point to hack, redesign, and improve.

It’s called the Piccolo:

It uses three (TINY!) servo motors, a bunch of laser cut gears and mounting plates, and some Processing-based software. Everything is open-source, and I don’t think they even sell any of the components themselves. They provide all of the files and expect people to make it on their own, which is kinda cool.

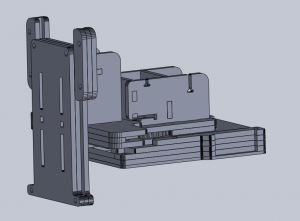

One thing I couldn’t find on their site anywhere was the work area. I needed dimensions of all of the parts to mount and design around this anyway, so a couple hours with their laser cutter files produced this:

Turns out all axis have a range of about 2.5 inches. That’s really tiny for a CNC platform, but definitely usable for making PCBs. At first, anyway. That double-ensures that this portion will eventually be replaced, probably with a CNC system of my own design. That will be fun, I am looking forward to it.

One note for future-self:

There is a decent chance that the sparking from my electrodes will cause enough interference to mess with my servos. If they get really jittery during a burn, I know exactly what is happening, and a redesign will happen sooner rather than later.

Working with the above files, I gathered together some more materials:

A 12V oil pump($12) for the EDM fluid (more on this in a future post), a standard heavy duty door hinge($3), and a small plastic tank($0.89). The tank is a lot smaller in person than it looks.

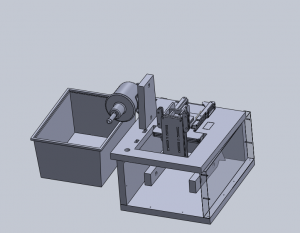

Putting it all together:

That’s a reasonably accurate mode of the tank on the left.

There’s also models of the Piccolo and the fuel pump that you can see there.

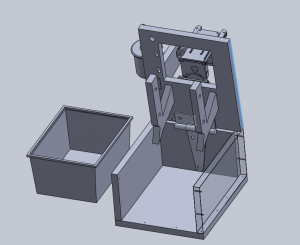

The rest of the frame is designed out of 1/2 inch MDF. The tank fits in the box, which can flip up like so:

And BAM. Hinges. The idea is that the whole mess can flip up for servicing, changing out the PCB, etc.

The PCB holders at the bottom might be changed a little before I build this, but the idea will stay the same. They’ll be submerged in the EDM fluid in the tank during operation. Afterwards, the top flips up, and those PCB holders are angled so that the oil drips back into the tank.

That should mitigate oil going everywhere somewhat. I still expect this to get messy.