I’m still transferring my SolidWorks knowledge into Fusion 360, and definitely getting the hang of it.

Previously, I was having troubles mating parts properly, which totally makes sense. The way Fusion 360 and SolidWorks handle these concepts are the largest difference in workflow so far.

Where SolidWorks requires each “part” to be one object, and all parts must be added to an “assembly” for positioning and mating, Fusion 360 allows all of these to happen in one file. When a part is created, however it is called a “body” and must be turned into a “component” before repositioning or aligning it with other component. I’m not sure the benefit of this, but hey, that’s how it works. After a body has been turned into components, the “joint” command is analogous to SolidWork’s “mates”. They’re a little bit more finicky, but they work.

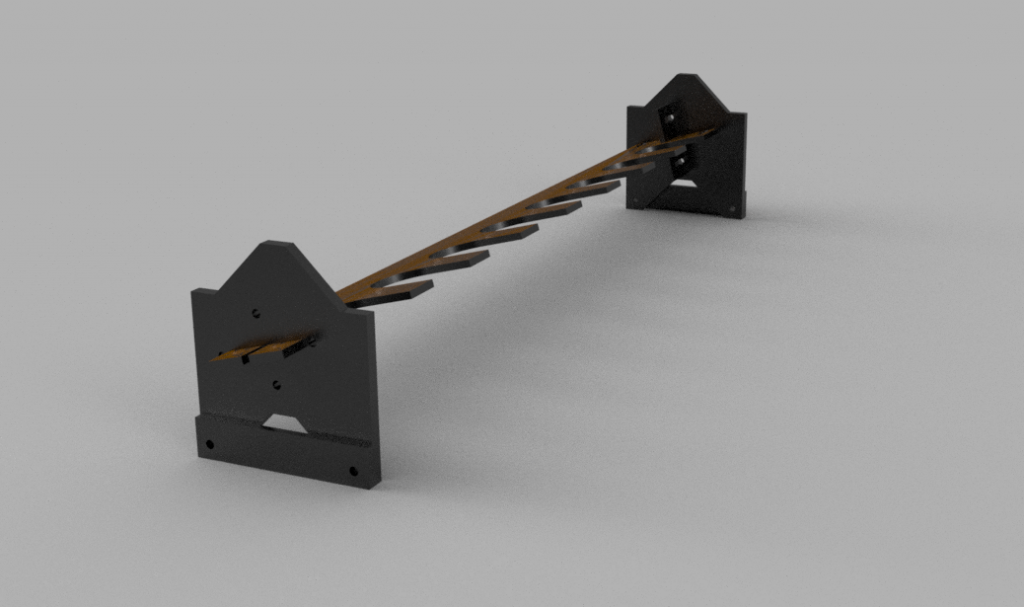

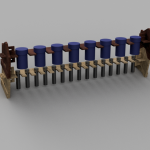

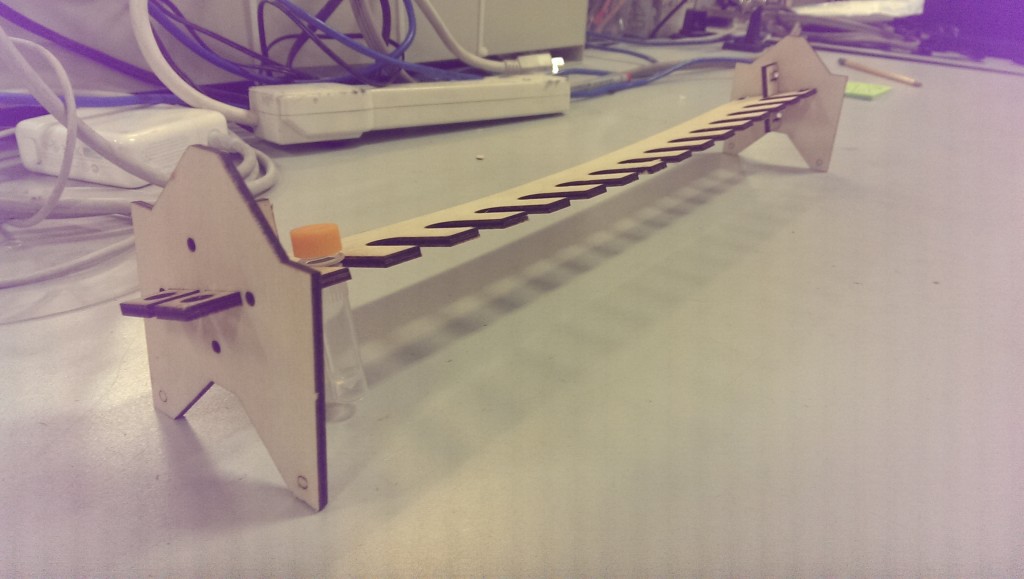

Here’s the latest experiment. Once again, this is almost entirely parametric. I had an idea to store all of my surface mount components in vials, and this is a pretty ideal way to stack them up. I realised about halfway through that, while designing a vial storage rack, it’s basically a spice rack.

One of the problems with this, is that over time I’ll be adding to it. Next time I need to laser cut some more, am I going to be able to find the same size of container? Am I going to be able to use the same size of material? What if I want a different sized rack to fit into a particular spot? Parametric!

There are a lot of variables in this one. Fortunately, most don’t have to be touched, usually.

In adapting these for different container size, the important variables are shelf_numVials and all of the vial_ parameters.

For the larger ones I got from the dollar store, they are:

vial_height = 48.75 – 11.5mm

vial_diameter = 27.5mm

vial_lidheight = 11.5mm

vial_lidDiameter = 31.25mm

These are unlikely to be available anywhere else.

The smaller ones from China are:

vial_height = 49 – 9mm

vial_diameter = 10.75mm

vial_lidheight = 9mm

vial_lidDiameter = 12.5mm

These are orange-lidded, 1.5mL plastic test tubes from AliExpress.

I’m now at revision 3 – The first one I cut sagged a little more than I would have liked, so I designed in a back piece at a right angle to straighten everything up.

That worked, and stacking R2 on top of the first version pushes the ends out – effectively pulling it straight.

All of my files are available on GitHub here, or through Autodesk’s weird cloud platform.

Here’s an older version showing them stack:

http://a360.co/1X4LDGb

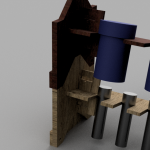

Here’s the latest version with all the bells and whistles:

http://a360.co/21Q52Bq

This is the one you want, if you’re planning on doing something similar.