In the time since I designed my timelapse camera gimbal, I’ve laid everything out for laser cutting, researched companies that offer cutting services, and very carefully decided not to send it out. As an initial draft, I wasn’t ready to spend $150 on a process that I’ve never used before.

Fortunately, the excellent Laser Cutter Cafe recently started up on a temporary basis. The deal is, you can come in, take a brief training course, and rent time on a laser cutter. Compare to online services, this is relatively inexpensive, and you can cut smaller test pieces and see the results immediately. For rapid prototyping, this is a valuable learning tool.

At the beginning, I was finding that many of my designs had fairly glaring errors that weren’t apparent until I was holding a physical copy. Throughout the process though, I was constantly tweaking and updating the design, and now I’ve got an excellent handle on what works and how everything will fit together.

The tweaking process involved adding, removing, and moving pieces around to fit better. Initially, everything was going to be glued together, but with a combination of finger joints and mortises, most of the individual components slot together and can almost friction fit. Naturally, glue will still be used, but the assembly of the final product is nearly idiot-proof now.

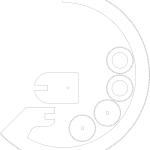

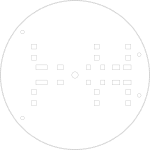

- 3/8″ Acrylic

- 3/8″ Acrylic

- 3/8″ Acrylic

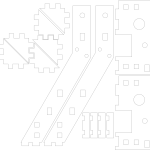

- 1/8″ Acrylic

- 3/8″ Plywood

- 3/8″ Plywood

If I were to print this again, I’d arrange the shapes closer, merging the the coincident lines to save on laser-time, but that wasn’t a priority while printing up the prototype.