People often ask me, “Jarrett, what is the Best Thing in Life?”

I’m not sure why people keep asking me this, but depending on my mood, the answer is one of two things: Floating on a lake, or swinging in a hammock. At peace with the world.

Frustrated by this bounty of choice that I just couldn’t narrow down, I began righting this wrong in the world.

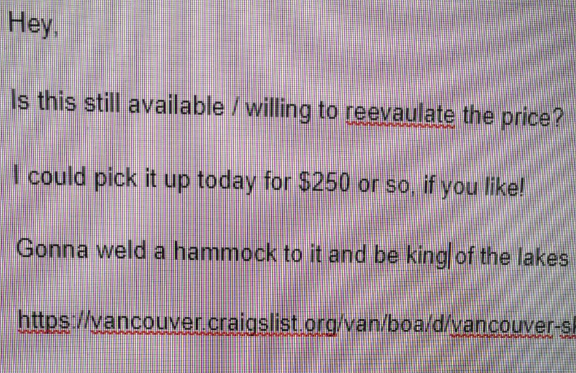

So I bought a boat.

And I bought a hammock.

And I bolted them together.

It even got me a sweet discount on the boat.

In truth, it actually took several false starts to build this successfully. Part of the challenge was that I wanted to avoid making any permanent modifications to either of the two structures, and the other difficulty is that while mulling over the challenges, well, I had a hammock in which to ponder design decisions. It’s nigh impossible to exit a hammock once you’ve settled in: fact.

The hammock frame is made out out of steel tubing, but the pontoon boat’s frame is aluminum. This made things a little challenging. No welding, really.

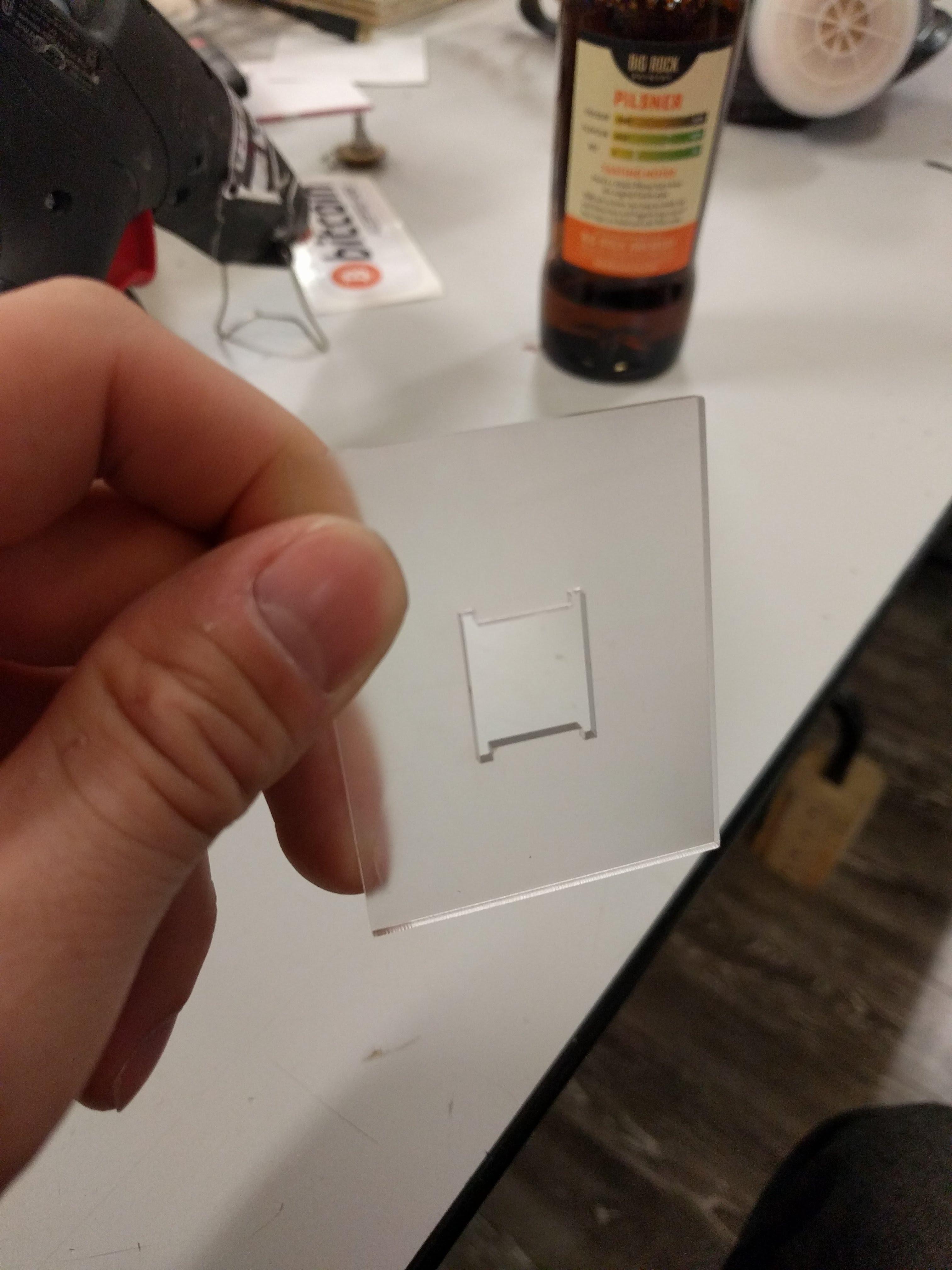

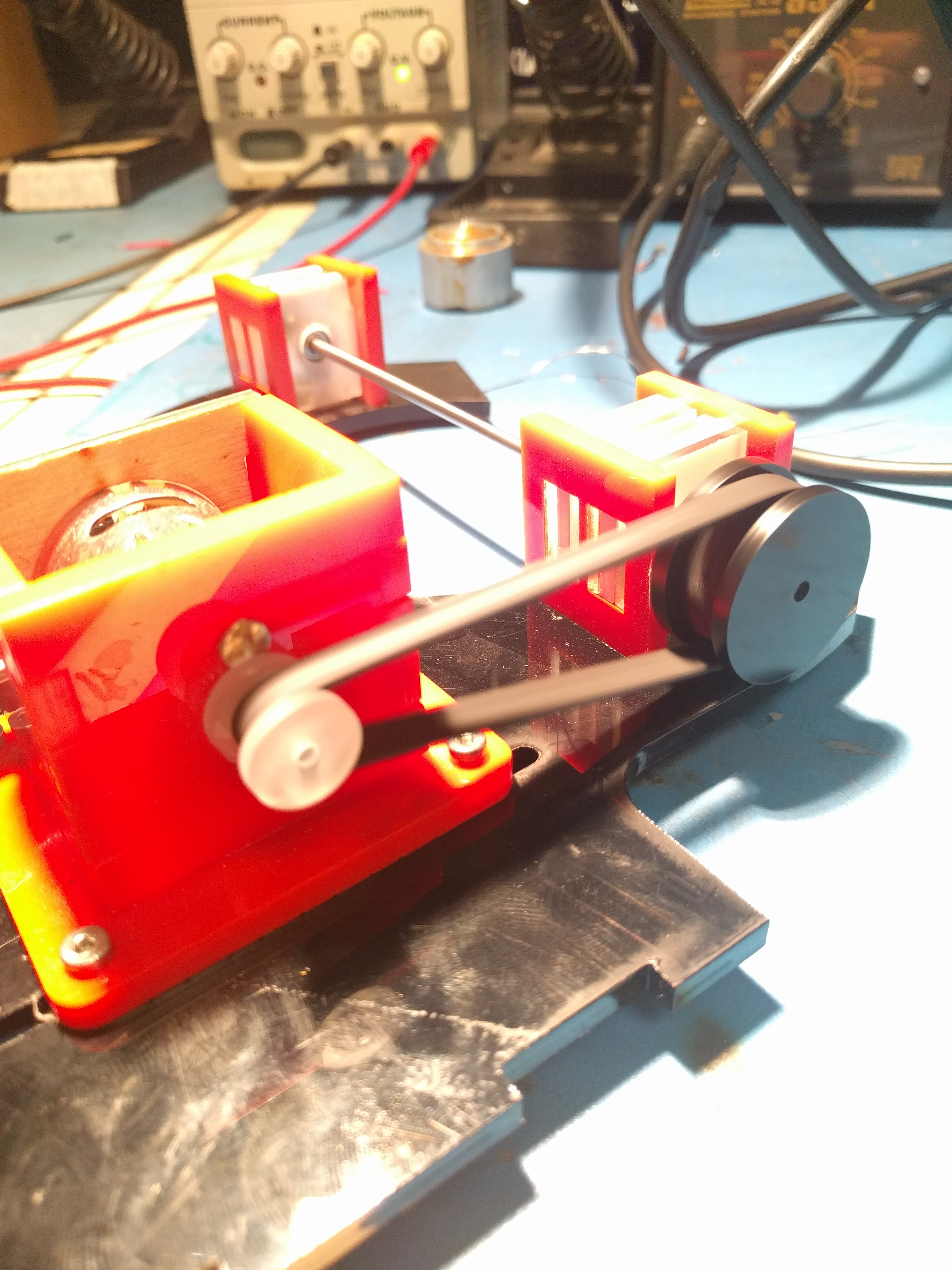

My first attempt used some steel flat stock.

I used a hydraulic press in an only sort-of-sketchy set-up to bend them in a half circle to go around the hammock frame’s steel tubing.

While putting any kind of weight on these, they’d bend distressingly, and have a sort of spring effect that I could see multiplying forces in weird ways, so I decided to abandon that route.

That made me sad, though, look at those bends!

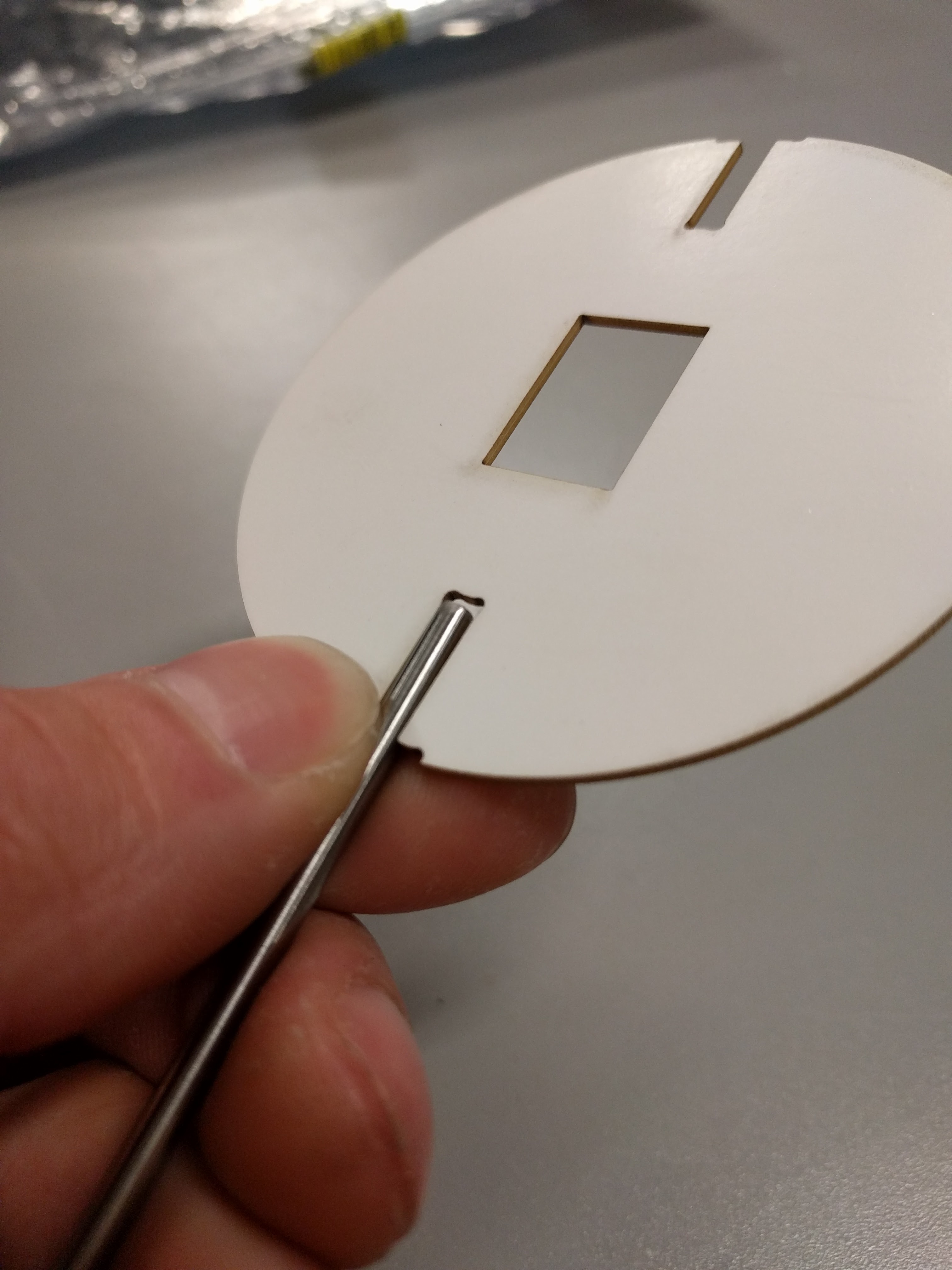

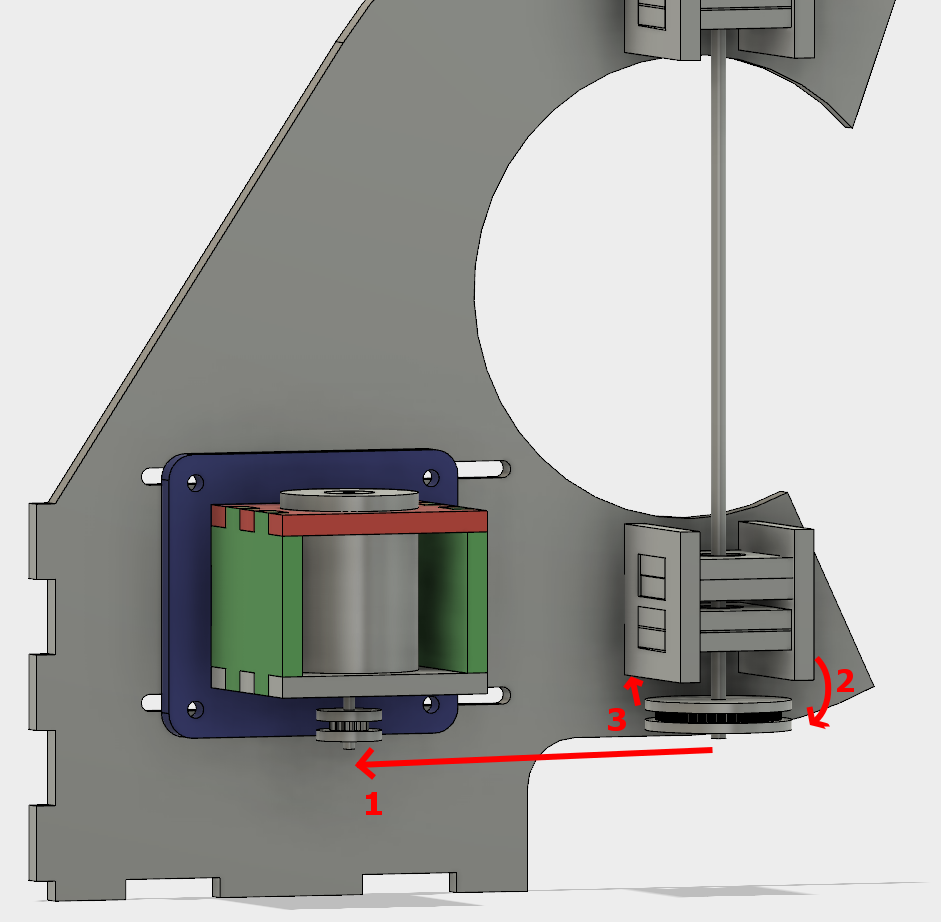

In parallel with the above, I also picked up some straps and built a method to fasten them around the pontoons.

Aluminum tube, a slit, and some filing (oh so much filing) did the trick, along with some new holes, bolts, and cotter pins.

Also positioning the whole contraption without mashing the pontoons against potentially sharp machine shop floor was tough. I finally settled on this lumber solution, which helped me see the final fastening solution.

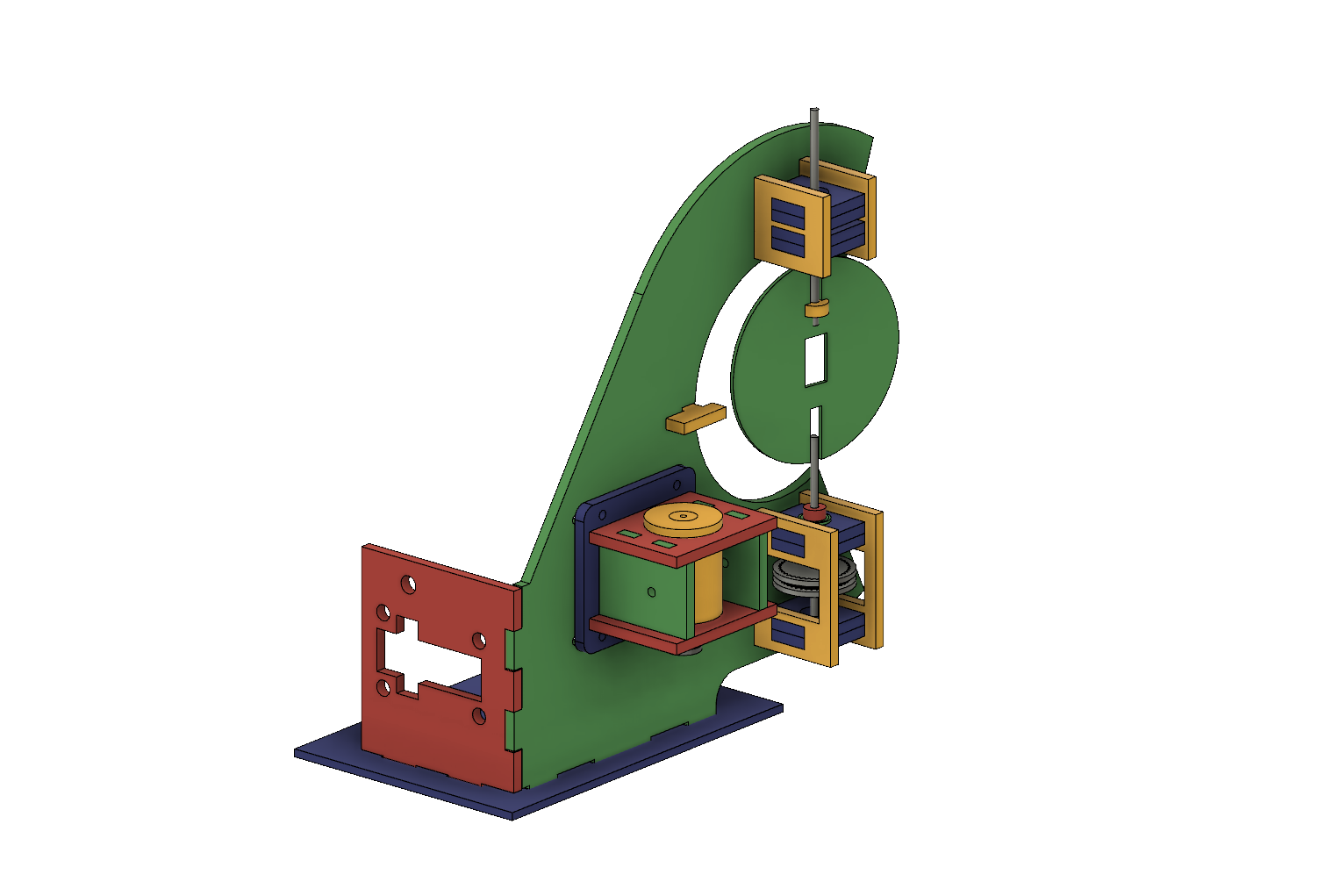

Back to the scrap bins, I found nearly the identical black anodized aluminum tubes that the pontoon boat is made out of. They slot right into the existing frame and couldn’t be more perfect. I hear they’re from an old bedframe.

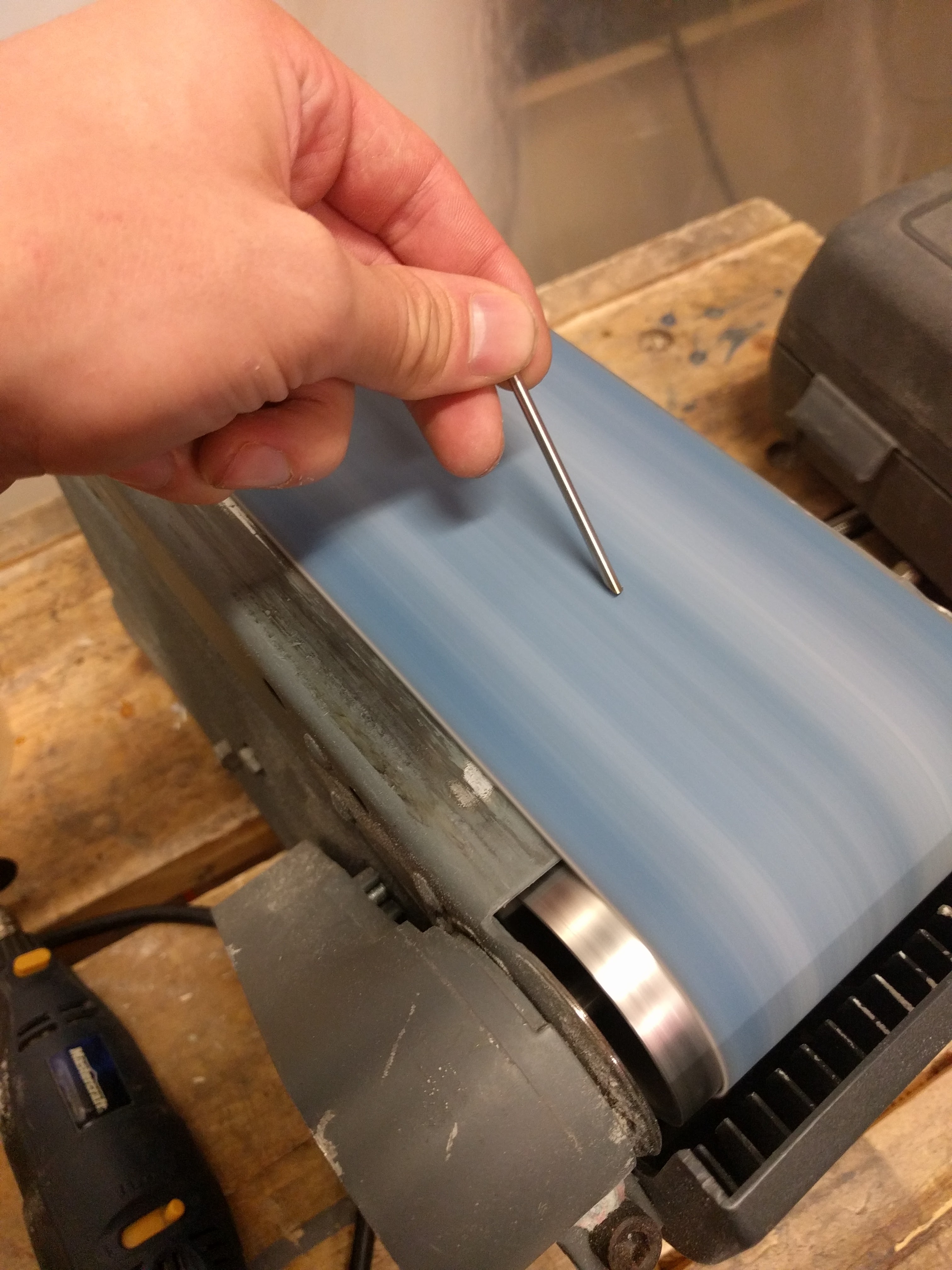

First I tried to bend one.

Then I tried harder to bend it.

Naturally, I kinked it, but I continued to try to bend it, this time using a convenient streetlamp garden decoration.

I still couldn’t get the bend angles I needed! Just not strong enough or heavy enough or clampy enough! I abandoned that attempt.

So attempt number, whatever.

I tossed two more of those scrap tubes into the boat frame, and clamped it on with some u-bolts.

Well that was easy. It brought the hammock a liitttle higher than I really wanted, but I decided to gopher it and fix it in rev 2 if it was a disaster. Summer is running out.

Before launch day, with much thought and much more relaxing hammock meditation, I decided that the boat tooootally had enough side-to-side stability, and that I’d have more issues front-to-back. This is because the hammock in resting position really wasn’t too much higher than the original boat’s seat, but the leverage on the hammock’s front/aft mounting points was way further out than the pontoons.

This later turned out to be completely correct.

But, burn that bridge when we get to it! I will probably add an outrigger to the back of the hammock frame. The water wings and pool noodles are not intended to be used, they’re just there as a last resort hammock rescue device, which we didn’t need.

And grab a couples friends and off we go.

Here’s the maiden voyage:

Spoiler:

But with a little more careful weight distribution, it works! It actually works really well, I was kinda blown away. It’s pretty much the best thing ever and I can’t believe it didn’t kill me.

Bliss.